|

| |

| 01 |

30-11--0001

azaz????l????l����������������������������������������������������������������������������... |

| .............................................................................................................. |

| 02 |

01-01-1970

No News Updates |

|

|

|

|

|

|

| |

|

|

|

|

| In process Quality checks |

In process Formats include multiple criteria for compliance to Quality Parameters In process Formats include multiple criteria for compliance to Quality Parameters

The formats flow through out the manufacturing process to monitor defects in the product throughout process cycle The formats flow through out the manufacturing process to monitor defects in the product throughout process cycle

Check list prepared specific to Check list prepared specific to

- inward inspection : of bare PCBs, Components, RM & consumables

- Process parameters : Dispensing, Stencil printing, Assembly, Temp. profiling of Reflow & wave soldering

- Final inspection : Criteria include specific customer inputs

- Testing : 100 % Test parameters tabulated as per Customer test procedures

|

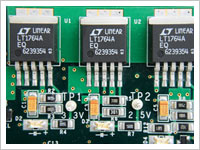

| In process Testing set up |

Component solderability tests Component solderability tests

Component reliability tests on functional test

circuits Component reliability tests on functional test

circuits

Tailor made pallets to identify missing components Tailor made pallets to identify missing components

Validation of Critical Processes viz. Component Placement And Soldering Validation of Critical Processes viz. Component Placement And Soldering

In House Test jig fabrication set up for ICT & FCT specific to product test requirements In House Test jig fabrication set up for ICT & FCT specific to product test requirements

Mechanical tooling ,fixtures devised to get consistent result during cutting, bending ,forming operations Mechanical tooling ,fixtures devised to get consistent result during cutting, bending ,forming operations

|

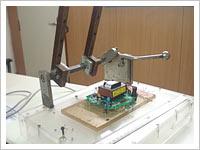

| In house Test Jigs fabrication capability |

| |

CAD net list ,Test Points generation. CAD net list ,Test Points generation.

Floor planning of physical layout of Test Set Up. Floor planning of physical layout of Test Set Up.

Matching test points & steps as per Test Procedures or sequence. Matching test points & steps as per Test Procedures or sequence.

Placement of Test Pins for bed of nails ,fixture fabrication. Placement of Test Pins for bed of nails ,fixture fabrication.

CNC data for mechanical fixing of test pins , bed of nails, receptacles ,support pins, guides. CNC data for mechanical fixing of test pins , bed of nails, receptacles ,support pins, guides.

Mechanical Assembly of test bench , wire wrapping , harnessing & soldering . Mechanical Assembly of test bench , wire wrapping , harnessing & soldering .

FCT Instrument Panel , Electrical Measurements & Display. FCT Instrument Panel , Electrical Measurements & Display.

ICT -Test programming as per BOM list , measuring parameters. ICT -Test programming as per BOM list , measuring parameters.

Forms or Formats to certify acquired data. Forms or Formats to certify acquired data.

Pass & Fail report , Register, Log book. Pass & Fail report , Register, Log book. |

| Test Methods : combination of MDA, ICT & FCT |

|

|

|

| Manufacturing Defect Analysis |

|

Check list for Functional test procedure |

|

|

|

|

| Customized Test Jigs |

|

System Ready for Final Functional Test |

|

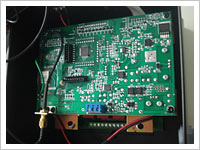

| Final Quality checking |

Product specific checklist prepared to ensure Product specific checklist prepared to ensure

Component orientation, height, mechanical dimensions and tolerances Component orientation, height, mechanical dimensions and tolerances

Adhesion of bulky components to prevent damage due to vibration and transport Adhesion of bulky components to prevent damage due to vibration and transport

Re inspection of rework Re inspection of rework

Final inspection for Solder quality and manufacturing defects Final inspection for Solder quality and manufacturing defects

Verification and approval of Functional Test reports Verification and approval of Functional Test reports

Traceability : Unique board identification number created Traceability : Unique board identification number created

|

| |

|

|

|